In January 2009, new revisions to ANSI standard Z358.1-2009 for emergency eyewash took effect. The most important thing is to make sure that emergency eyewash stations are installed and maintained correctly. There are some basic requirements of ANSI which include:

- A means of flushing injured eyes must be available at the site of any hazardous materials.

- Eyewash must be within a 10-second walk of the hazard

- An injured person must be able to flush their eyes for a full 15 minutes.

- ANSI also calls out the rate of flow, fluid angle, temperature, user’s position, and station location, installation and maintenance.

With that said, there are five steps that your business can take to ensure that you are in compliance with the ANSI emergency eyewash standards.

- Assess your facility to determine if your site requires emergency eyewash.

Most businesses are required to have eyewash stations if any of the following hazards are at the site: paint, solvents, battery charging stations, hazardous chemical storage, tool parts washers, or chemical pumping/mixing areas. Also,If employees use chemical-resistant gloves, cartridge or air-supplied respirators, chemical-resistant goggles or flammable storage containers, emergency eyewash is also required.

- Choose the right eyewash system for your facility

There are several questions that you can ask to determine your needs:

- What are the most common hazards?

- Does the workspace layout change as new jobs commence?

- Is plumbing readily available at the site of every eye hazard?

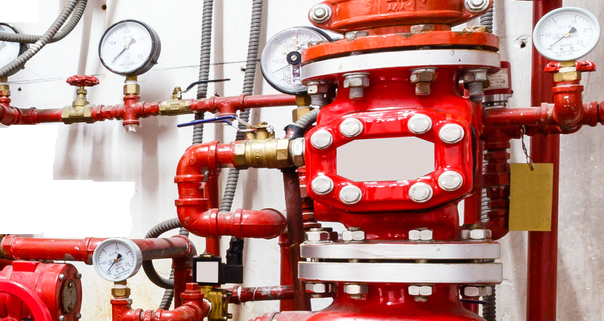

There are two types of primary emergency eyewash delivery stations to consider: plumbed and portable. Plumbed eyewash units deliver plumbed tap water to the eyes in plentiful amounts. The downside of plumbed stations is that they are expensive to install, impractical to move and require weekly maintenance. Another problem with the plumbed systems is that they use tap water. Because its temperature is not easily regulated, plumbed tap water is often too hot or too cold to flush with for the required 15 minutes. Also, since It does not match the eye’s natural pH, so flushing with it can cause irritation.

The alternative is portable stations, which come in many varieties to meet a wide variety of needs. These systems contain water, saline solution or 100 percent sterile saline, each of which is maintained at room temperature inside the unit. Stations that deliver sterile flushing fluid offer the best possible safety and because they are devoid of harmful impurities, sterile saline reduces employers’ risk of liability if further injury results.

- Emergency Eyewash must be Readily Accessible

It is important to remember that an injured worker may have limited or no vision if an emergency occurs, so it is important to select a location for the unit that is quickly and easily accessible during an emergency. ANSI specifies that stations be located within a 10-second walk from the hazard and on a travel path from the hazard that is free of obstructions. It must also be on the same level as the hazard (no stairs) and in an area that is well lit and clearly marked with a sign.

- It is critical to train employees on proper emergency response

It is the your responsibility to ensure that every employee is trained in using emergency eyewash units. Employees must know how to get to the eyewash station and must know how to activate the system in order to properly rinse contaminants from their eyes. The proper flushing technique calls for the worker to hold both eyes open with their forefingers and thumbs and let the fluid rinse across the eyes from the inside corner out for 15 minutes.

- Develop a safety plan that encompasses eyewash safety

The best way to ensure eyewash compliance in the workplace is by building it into the company’s safety plan. Employ a safety manager, assign safety stewards or use a third-party vendor to be responsible for employee training and station maintenance. The appointed safety leader should train staff regularly as a group and new associates as they join.

It is also important for your company to maintain eyewash units as required according to ANSI and/or the manufacturer. Plumbed stations require the most maintenance – they must be activated weekly to get rid of particle buildup in the pipes. According to OSHA, a weekly activation “long enough to verify operation and ensure that flushing fluid is available,” is required. Portable units require less frequent maintenance but still need to be cleaned and disinfected every 3-6 months.

VFS Fire & Security Services has extensive experience in working with eyewash systems. Our team of experts can help with system design, plumbing, compliance and system maintenance. Contact us today to learn more about our services.