Frequent fire protection system inspections and maintenance are essential in protecting your property and, more importantly, your people. But, building owners may have questions such as: who can inspect my fire protection systems? Do they need a license? How often should the systems be inspected? What will be covered in the inspection?

First, What is a Fire Safety Inspection?

A fire safety inspection is a necessary examination of a building or structure and its relevant fire safety documents. A fire safety inspection measures how well your building is managed in regard to fire safety.

Legally, buildings must comply with a set of building codes and ordinances to keep their occupants safe. A fire safety inspection ensures you are doing so and calculates the potential risk factor in a given facility.

Who Can Inspect and Maintain My Fire Protection Systems?

This is a tricky question that does not, unfortunately, have one answer. Why? NFPA standards aren’t clear on who, exactly, may work with a fire protection system across the United States. NFPA 25 requires that those engaging in inspection, testing, and maintenance must be “qualified.” The meaning of “qualified” may be left up to individual jurisdictions.

However, if you own a building in California, there are some clear rules to follow. Let’s take a look.

In California, a license is required to test or maintain a fire sprinkler system.

From the California Health and Safety Code:

“13196.5. (a) Except as provided in subdivisions (b), (c), and (d), no person shall engage in the business of servicing or testing automatic fire extinguishing systems without a license issued by the State Fire Marshal pursuant to this chapter.”

We understand that maintaining fire sprinkler systems can be complicated. If you have questions, we have answers. Reach out to us today if you are unsure who should inspect your fire protection system.

Who is Responsible For Ensuring All Systems Are Properly Maintained?

According to NFPA 72, National Fire Alarm and Signaling Code, the owner is responsible for inspections, testing, and maintenance, as well as any alterations or additions to the fire alarm system.

If your building’s fire system is being regularly inspected and is up to code, it significantly decreases the probability that your property will be destroyed in the event of a fire.

How Often Should Fire System Inspections Occur?

According to the NFPA code, inspections of your fire and life safety systems are required to occur on a quarterly and annual basis.

What is NFPA Code?

The National Fire Protection Association (NFPA) has over 300 codes and standards that apply to nearly all buildings, services, installations, and processes. NFPA codes are designed to reduce or minimize the effects of fires and other safety risks.

A little intimidated to start reading 300 NFPA codes and standards? That’s okay- we get it! Begin by checking out this article, where we break down a couple of codes you should know.

What Will Be On My Inspection Report?

Your inspection report will include:

- The location of every device in the building

- Whether each device passed or failed inspection

- The reasons why each device passed or failed inspection

- Date and time stamps of when each device was inspected

- Device inventory

- Device warranty status

- Indication of the length of time devices have been in service

- Verification of report results

Do All Fire System Components Need to Be Checked With The Same Frequency?

Some components of a fire system need to be checked more often than others.

For instance, a fire pump may require weekly or monthly inspections, whereas sprinkler systems may only need a quarterly check.

Need Help With Inspections and Maintenance?

At VFS, we partner with our clients to ensure their maintenance and inspections are scheduled and performed regularly. The expert team at VFS Fire & Security Services has the breadth of knowledge to provide all regular scheduled and code-mandated fire protection system inspections. We have a diverse team of experienced fire protection professionals capable of inspecting and servicing even the most complex fire protection systems.

Our advanced platforms and highly trained dispatch team allow us to manage inspections and testing from inception to execution. We tell you what’s due when it’s due, and why it’s due, and we constantly communicate with your team to keep you up-to-date on the latest information within your facilities. Allow us to be your trusted Inspector Gadget and take on all your inspection and maintenance needs.

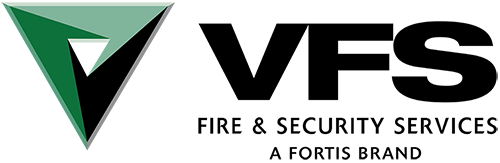

Do you have your inspection already scheduled? Here’s how to prepare for a fire safety inspection before it occurs.