We’ll be honest… “Stop, drop, and roll” paired with a colorful poster in your company’s break room isn’t going to cut it. Proper fire safety training saves lives, time, and money and is essential in any workforce or industry.

Nearly 4,000 people die in fires each year in the United States; that is eleven fire-related deaths per day. Additionally, the U.S. Fire Administration estimates that fires in commercial buildings cost owners over $2.4 billion per year.

Let’s not contribute to these statistics! Instead, employers can help prevent injuries, losses, and damages by implementing proper fire safety training in the workplace.

We’ll break down the basics of fire safety training, starting with the Occupational Safety and Health Administration (OSHA) requirements.

What Are OSHA’s Requirements for Fire Safety Training in the Workplace?

Under the Occupational Safety and Health Act of 1970, employers are responsible for providing a “safe and healthful workplace.” Therefore, fire safety training is required in most American workplaces.

Basic Requirements

The minimum requirements outlined by the Occupational Safety and Health Administration ensure employees know how to protect themselves in the event of a fire. To summarize:

- Employees know how to recognize the signs of a fire

- Employees understand how to safely evacuate the building

Requirements Per Industry

OSHA requirements are different in each industry. OSHA categorizes its standards into five sections:

- General Industry

- Maritime

- Construction

- Agriculture

- Federal Employment Programs

Each of these categories contains specific information that employers may find useful in planning fire safety training for employees in their industry. For more information, check out the booklet OSHA provided for training requirements.

Now, let’s look at how to implement fire safety training outside of the minimum requirements.

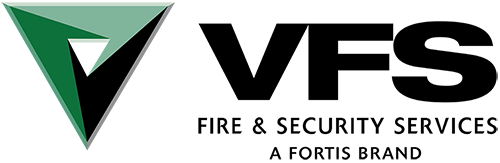

How to Implement Fire Safety Training in Your Workplace

Outline Your Goals

First, fire safety training should begin with an analysis of your goals and objectives for the training. Employers may ask themselves the following questions:

- What do I want my team to gain from this training?

- What points do I need to cover for their safety?

- What do I want today’s training to accomplish?

- What do I want this training to improve in the future?

- How many training sessions will allow me to present this information to my team?

- What resources does my team already have?

- What resources do my employees need to reach these safety goals?

Develop a Fire Safety Plan

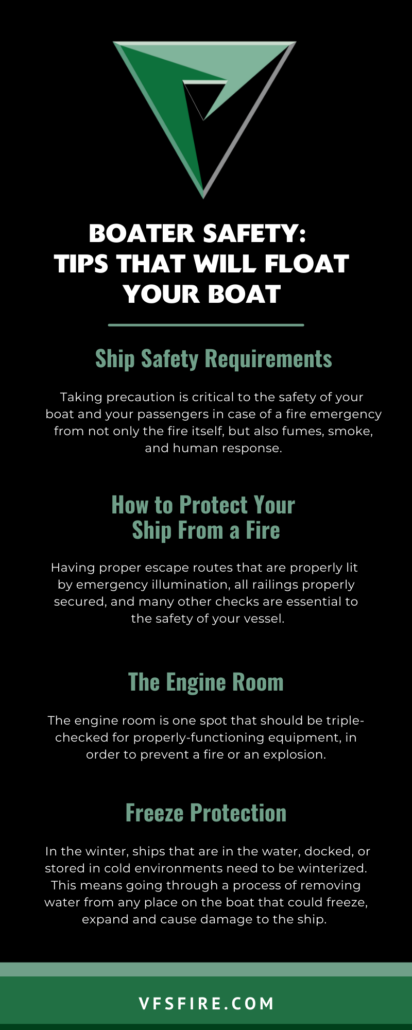

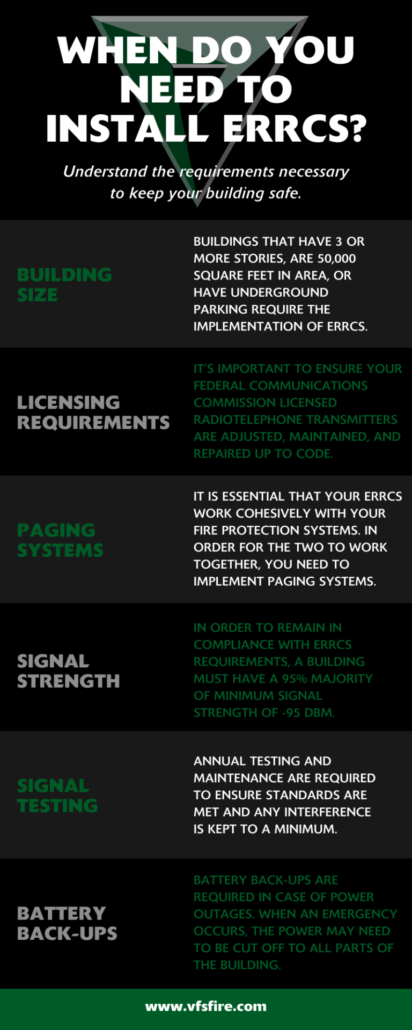

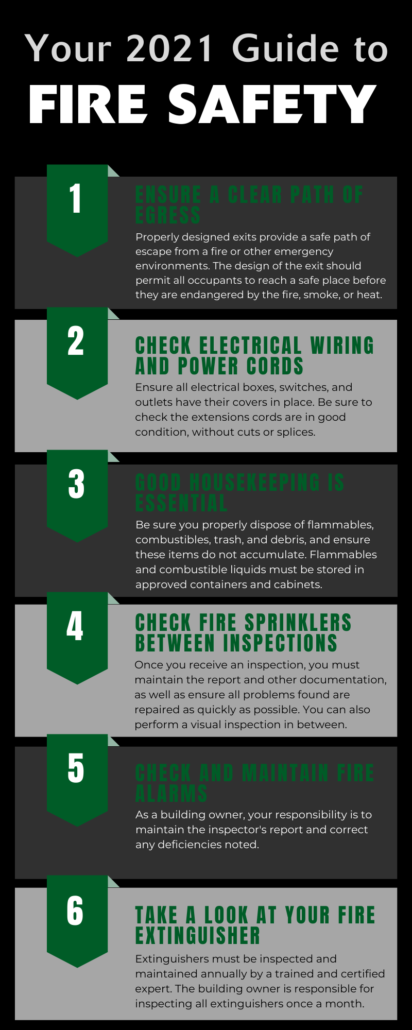

If your organization hasn’t already, it is crucial to develop a fire safety plan. To build an efficient plan, employers and employees should be familiar with:

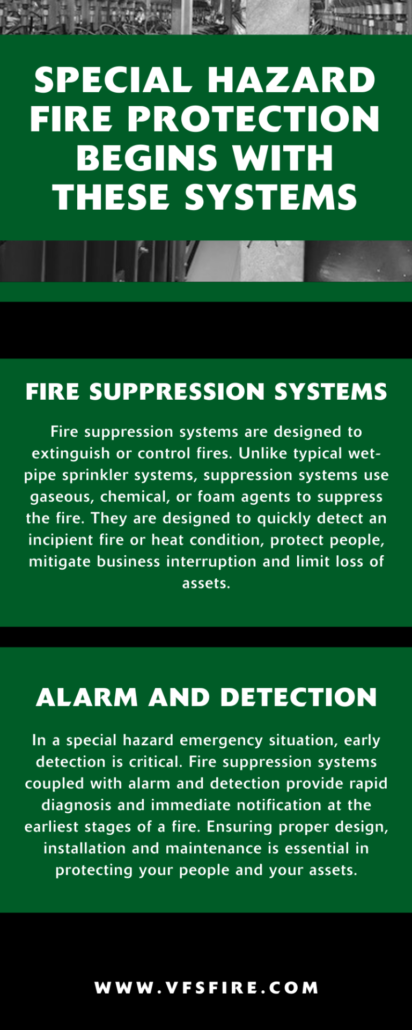

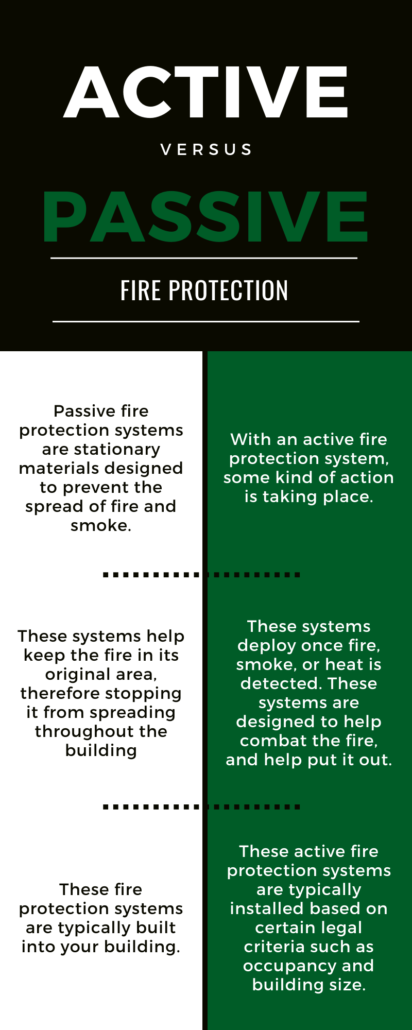

- The type of fire suppression or alarm system in the building

- All exits in the building

- A list of all major fire hazards

- Potential fuel sources for fires

- The types and locations of fire protection equipment in the building

Once the employer has collected this information, they can form a plan and present it to their team.

Presenting a Fire Safety Plan

Employers should take time to ensure their team understands their workplace’s fire safety plan.

For instance, employees should have a complete understanding of:

- Where fire protection equipment is located and how to use it

- Expectations for if they are the first to see a fire in the workplace

- How they will communicate with their team in the event of a fire

- The route they will use to evacuate the building

- Options to exit the building

- How to activate the fire alarm

- When to call 911

- A location to regroup outside of the building

Every workplace may have slightly different safety plans, procedures, and requirements.

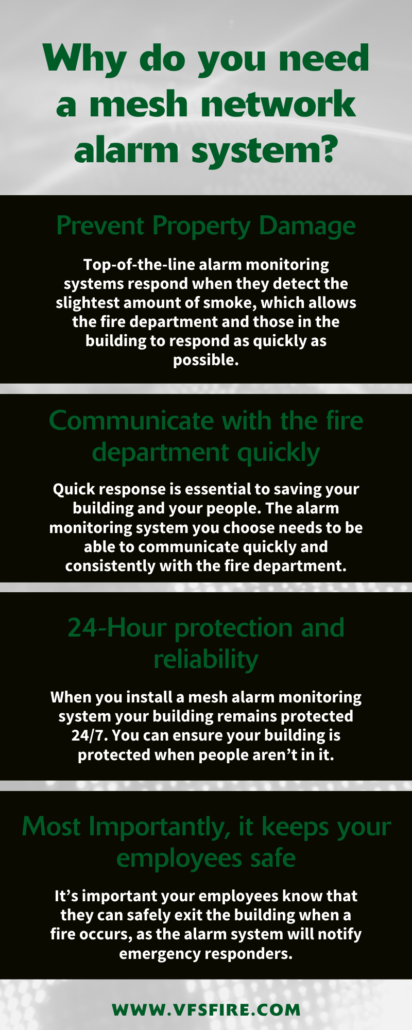

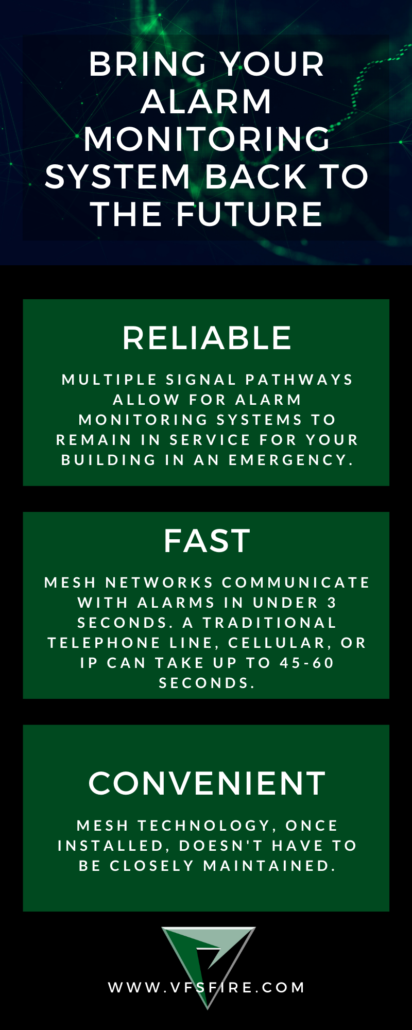

Don’t want to rely on an employee to notify emergency services of the fire? Consider a monitored fire alarm system.

Why? Suppose the building is equipped with a non-monitored fire alarm system. In that case, the fire department will only be dispatched when someone manages to call 911.

Additionally, leaders should consider the following topics when crafting their workplace fire safety training.

Workplace Fire Safety Training Topics

Fire safety training in the workplace can vary depending on the company and industry. However, all workplace training should include a general overview of basic topics to ensure employee safety and help protect property against damages.

Fire Prevention

An employer’s primary goal in fire safety training should be to stop the fire from happening in the first place.

Fire prevention training may have the goals of:

- How to recognize fire hazards

- How to reduce the risk of hazardous situations

- Steps to fix or reduce a fire risk

Hazard Recognition

If employees know the most common causes of fires, they will be more successful in preventing similar situations in the future.

According to the National Fire Protection Association (NFPA), the most common causes of fires in commercial buildings are:

- Cooking equipment

- Heating equipment

- Electrical and lighting equipment

- Smoking materials

- Intentional fire setting

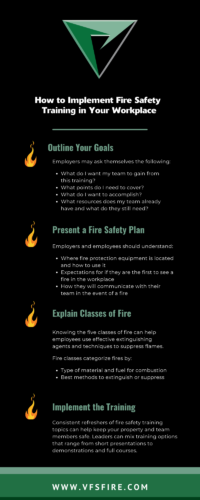

Types of Fires and How to Contain Them

In the event of a fire, knowing the five classes of fire can help employees use the most effective fire extinguishing agents and techniques to safely suppress flames.

Fire classes—which include Class A, Class B, Class C, Class D, and Class K—are a means of categorizing fires by factors such as:

- The type of material and fuel for combustion

- The best methods to extinguish or suppress them

Read on for more detail on the five classes of fires and how to contain them.

How to Implement Fire Safety Trainings

Employers should be mindful of OSHA’s guidelines and local codes, then pass this information to their team.

Additionally, consistent refreshers of fire safety training topics can help keep your property and team members safe. Leaders can mix training options that range from short presentations to demonstrations and full courses.

Looking For Other Ways to Protect Your Team or Commercial Building?

At VFS Fire & Security Services, our mission is to grow our business by serving our community and protecting what matters most to our clients; life and valued assets.

For more information, check out our fire protection solutions.