It’s Lit! Holiday Fire Safety Tips for Roasting Chestnuts on an Open Fire

JK… Open Fires are Very Dangerous

It’s almost the New Year, and you know what that means… it’s time to light it up! But be careful. 2021 has shown us you can never be too careful when it comes to health and safety. In other words, don’t go out of 2021 with a literal bang…

Keep in mind a few fire safety precautions as you ring in the new year. We’re a fire prevention company, so what else would we be talking about going into the New Year? Here are some fire safety tips to consider.

YOUR SMOKE DETECTOR MAY BE ANNOYING, BUT THERE’S A REASON

We understand the ringing from a smoke detector is the last thing you want to hear during the holidays. (Depending on who you ask, it’s arguably better than hearing Mariah Carey’s ‘All I Want’ for the 100th time though…)

Regardless, smoke detectors have a purpose and that purpose is to keep you safe. Be sure your smoke detectors are up-to-date and have working batteries as you ring in the new year.

JUST LIKE THE AIRPORT, UNATTENDED BAGGAGE – IN THIS CASE, POTS AND PANS – SHOULD BE SUBJECT TO REMOVAL

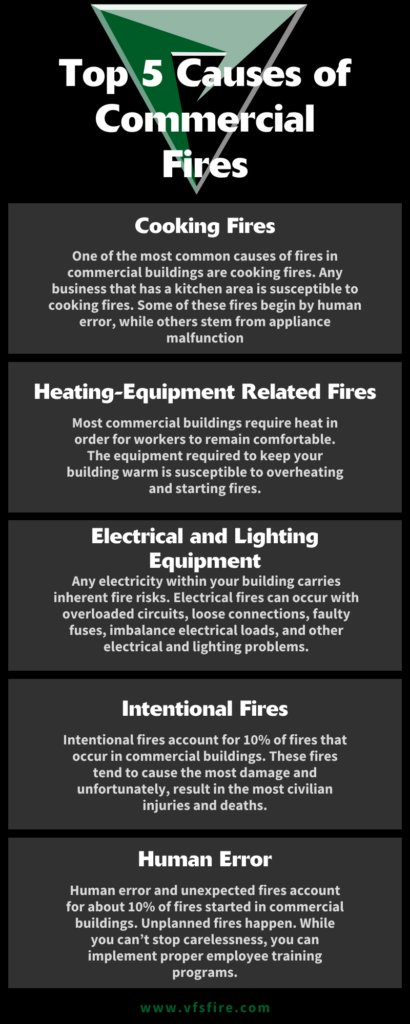

The holiday season brings about quite a few family dinners and get-togethers that are centered around a meal. With aunts, uncles, or even just your immediate family, the kitchen can get a bit chaotic during the holiday season. It’s easy to become overwhelmed and distracted, and potentially forget about a pan on the stove or a simmering pot. Yikes!

Did you know the majority of kitchen fires begin with unattended pots and pans? While you’re cooking it’s important to remain present and aware of your surroundings.

Another useful tip is to keep clutter to a minimum, especially in the kitchen.

ROCKIN’ AROUND AN OPEN FLAME JUST ISN’T AS CATCHY…

The glow of your Christmas tree is beautiful, we agree; however, be sure you take precautions to ensure your safety. Christmas trees are one of the most common fire hazards during the holidays.

Make sure your tree remains hydrated and away from heat sources. According to the National Fire Protection Association (NFPA), 25% of the Christmas tree fires that occur do so because the tree was too close to a heat source, like a candle or space heater.

YES, WE KNOW IT IS COLD, YES, THE AMBIANCE OF YOUR FIREPLACE IS PERFECT, BUT PLEASE BE CAREFUL

According to the NFPA, heating equipment is the second cause of house fires each year. We understand that heating your home is important.

You want to stay warm and cozy during these cold months, but you also need to stay safe. The last thing you want is to be standing out in the freezing cold while the fire department hoses down your house…

When using a space heater, ensure it is at least three feet from flammable items, including decor, upholstery, and Christmas trees.

As far as your fireplace goes, be sure your damper is open, a protective screen is in play, and gifts and other items remain far away. Fireplaces can crackle and release embers that could spark into something more dangerous than being on the naughty list.

OVERPACKING YOUR OUTLET IS NOT LIKE OVERPACKING FOR YOUR HOLIDAY VACATION… IT’S WORSE!

While there are plenty of things that need to be plugged in during the holiday season, it’s important not to overcrowd outlets. Electrical shorts and malfunctions are some of the leading causes of electrical fires.

As you string your lights and plug more decor into an outlet, be sure the outlet’s total load does not exceed 15 amps. While it may be tempting to have your house shining at all times during the holidays, turn off your decor when you leave the house and when you go to bed as a safety precaution.

BE AWARE OF INDOOR AND OUTDOOR DECOR

As you decorate for each respective holiday, it’s important to test all lights and cords. Then, replace anything faulty prior to use. Candles should be placed out of reach of children and be sure to extinguish them before you leave the room.

As far as outdoor decor goes, only use extension cords and light displays intended for outdoor use. Those cords should be kept away from both snow and standing water to avoid damage to the insulation.

Cords should not be pinched in doors, windows, or placed under furniture. Keep in mind, metal ladders conduct electricity, so opt for a wood or fiberglass ladder instead.

THE LAST THING YOU NEED THIS YEAR IS TO LOSE A FINGER, BE CAREFUL WITH YOUR FIREWORKS

You may want to celebrate the start of 2022 with fireworks. We understand, it’s tradition. It’s important, however, to be aware of the safety hazards that come with fireworks.

If you choose to set off fireworks on your own:

- Check local laws prior

- Choose a location away from buildings and trees

- Ensure any spectators stand well away from the site

- Keep water or a fire extinguisher close by in case of emergency

As we Californians know, if you’re experiencing a drought in your area, it is recommended that you cancel the fireworks show altogether.

While all of these safety precautions may seem daunting or even annoying as you tackle the holidays, they are extremely important to your safety. From our team at VFS, we wish you a happy and safe holiday season!

Speaking of stressful seasons, are you worried about preparing your property for hurricane season? Read how to prepare on our blog.