A fire protection system is a crucial part of any fire protection infrastructure protecting any building.

The Global Fire Suppression Systems Market Report discusses the growth of the fire suppression market and answers questions such as: How much is the fire suppression system market growing? Why is it growing? What does this mean for the future of the fire protection industry?

In this blog, we will summarize some significant findings of the report and discuss what these findings could mean for the fire protection industry.

What is the Fire Suppression Systems Market Report 2022?

The Fire Suppression Market Report analyzes and forecasts the market based on:

- Suppression reagent

- Product

- Sector

- Geography

Let’s take a look at some of the report’s predictions.

The Fire Suppression System Market Will Witness Significant Growth

The fire suppression market has experienced significant growth in the past few years. In fact, in 2018, the fire suppression market was projected to reach USD 29.13 billion by 2023, at a CAGR of 4.87% between 2018 and 2023.

In 2021, the global fire suppression system market size was valued at USD 16.8 billion and is expected to witness a CAGR of 4.8% from 2022 to 2030.

What do these statistics tell us? The fire suppression system market has experienced significant growth and shows no signs of slowing; this growth will likely continue well into the 2030’s.

What Caused the Growth in the Fire Suppression Industry?

The growth can be attributed to several factors. For instance, these factors may include:

- The growing importance on preventing casualties and damage to infrastructure due to fire breakouts

- Rising awareness among consumers about the latest fire protection systems

Fire suppression systems can be considered one of the critical systems installed in buildings or establishments. Fire suppression systems play a vital role in protecting people and properties in the event of a fire accident.

How Did the COVID-19 Pandemic Slow the Growth of the Industry?

The 2018 Global Fire Suppression System Market Report predicted massive growth in the industry and while there was still growth, the report could not consider the effects of the COVID-19 pandemic.

The effects of the pandemic, most prevalent in 2020 and 2021, rippled throughout the fire protection industry. For instance:

Delayed Fire Suppression System Installation

The outbreak of the COVID-19 pandemic caused a series of lockdowns throughout the world as part of an effort to stop the spread of the virus. These lockdowns resulted in the pause or delay of many fire suppression system installations at various locations in 2020 and some of 2021.

However, as restrictions are lifted, these installations will likely be finished.

Production

The COVID-19 pandemic exposed any weak links or inefficient areas in supply chains by creating a series of issues that trickled down the chain. These issues are caused by any lockdowns, ordinances or regulations leading to a labor shortage and deficit in materials.

As a result of the pandemic, freight costs spiked, shipments were delayed and the costs of goods experienced a severe increase. The production of fire suppression equipment has been disrupted by these issues, some production activities have been suspended temporarily.

Similarly to the fire suppression system installations, the production of these systems is poised for growth once restrictions are gradually lifted and supply chains become more efficient.

Why is the Fire Suppression Industry Expected to Grow More in 2023?

An increase in demand, regulatory mandates and a growing demand for environmentally friendly systems are all contributing factors to the continuous growth of the industry. Let’s take a closer look at each of these.

Increased Demand

The Fire Suppression Market Report predicts increasing demand for fire protection systems from:

- Manufacturing units

- Incumbents of various industries and industry verticals, such as oil and gas, energy, and power

These industries are expected to drive the demand for fire suppression systems over the forecast period. Additionally, many system installations that were delayed during the pandemic will likely be continued throughout 2023, contributing to the increase in demand.

Regulatory Mandates

According to the Fire Suppression Market Report, regulatory mandates and the adoption of fire safety standards across the globe will contribute to the growth of the industry.

These mandates – caused by an increasing number of fire accidents – may lead to the installation of fire suppression systems in residential and commercial buildings.

Insurance Requirements

Additionally, some insurance agencies are considering making the installation of these systems mandatory before they will insure any building. This may lead to systems being installed in buildings such as:

- Households

- Residential apartments

- Hotels

- Schools

- Hospitals

- Restaurants

- Offices

These insurance requirements will likely cause many building owners who previously did not have a fire suppression system to invest in one, driving growth in the industry.

Growing Demand for Environmentally Friendly Systems

Lastly, the Fire Suppression Market Report predicts a spike in demand for environment-friendly fire suppression systems.

These systems are most commonly used in newly constructed infrastructure, such as in residential, commercial and industrial construction.

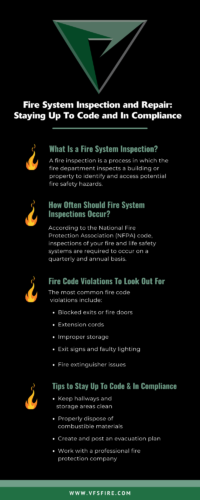

Ready To Have Your Systems Inspected? Consider VFS Fire and Security

Ensure your building is safe and up to fire protection code compliance by partnering with a company that specializes in fire protection. With over 300 NFPA codes and standards, the rules can get complicated quickly– especially if you don’t know exactly what you’re looking for. Luckily, we do.

At VFS Fire and Security, we offer a range of services to make sure your building is safe and in compliance. Start a conversation with us today.

Still have more questions about your building’s compliance? We’ve got you covered with our building compliance cheat sheet.