It’s summertime! Time for dancing, talking, and sunshine. Maybe you’re feeling rusty with your social skills, and have a big party coming up without any amazing talking points.

Well, might as well give it a shot with different types of sprinklers! (But here’s a major hint: leave the sprinkler dance at home. You know, that cringy 80s dance move…) Here’s a rundown of different sprinkler systems for national fire prevention.

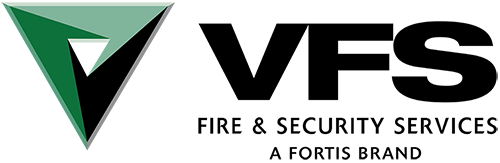

Wet Pipe System

These systems are the most popular sprinkler systems. They are extremely effective, low-cost, and low-maintenance. The system’s pipes remain filled with water. Once triggered by the heat source, water flows through the activated sprinkler to the source of the fire. These systems are extremely quick in reacting to potential fires; however, they are at risk of freezing in cold environments.

Dry Pipe System

In freezing climates, dry pipe sprinkler systems are a more suitable choice than wet pipe systems. These systems do not carry water in the piping until activation.

Instead, these pipes are filled with pressurized air and nitrogen. When the system is activated, the valve opens and water flows in when the sprinkler head is triggered.

As the water is not housed in the actual piping, you can guess that the disadvantage of dry pipe systems is that their response time is delayed. Another potential downfall to these systems is the required maintenance. Sprinkler corrosion is more prevalent in these systems, as the compressed air and oxygen create an enticing environment for corrosion.

Pre-Action System

Pre-action sprinkler systems are used to protect areas where water damage from damaged sprinklers or piping needs to be avoided. These are the middle ground between dry and wet fire protection systems.

Water is not contained in the sprinkler piping and is held back by a pre-action valve. The valve is opened when flame, heat, or smoke is detected. The detection system must detect a fire and the valve must open to initiate water to flow within the pipes. These systems are ideal for water-sensitive environments such as museums, data centers, libraries, vaults, and freezer warehouses as they carry a low risk of accidental discharge. They prevent excessive water damage and work ideally in cold conditions as the water is not held within the pipes to prevent freezing in the pipes.

Deluge System

Deluge suppression systems are typically used in special hazard installations when water must be applied to an entire area for fire protection. These systems are considered a ‘dry fire protection system’ as the piping for the system is empty and at atmospheric pressure with the sprinkler heads open. When heat or fire is detected by the system, the deluge valve releases the water, dry chemicals, inert gases, or foam.

These systems are typically used for facilities where an entire area needs to be protected immediately; rather than by a zone or specific location of the source of the heat or fire. Typical facilities that utilize deluge suppression systems are airport hangars, chemical plants, processing plants, and data storage centers. These systems are especially useful when you need to quickly flood an area to prevent a fire from growing.

Foam Water Systems

Foam Water Systems

Foam water systems are a type of wet sprinkler system that combines both water and a foaming agent for large-scale fire extinguishment. These specific irrigation systems are generally installed in facilities where extinguishing a fire can be more challenging than usual, due to the flammable and combustible contents housed within.

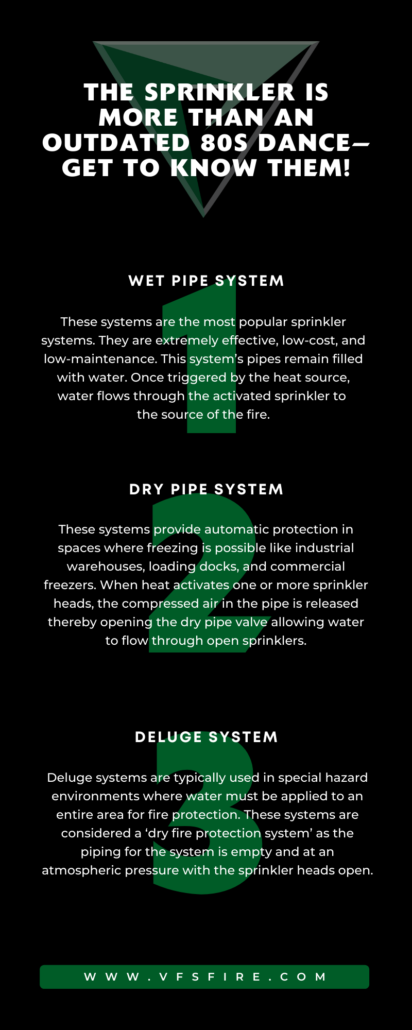

Additional Fire Safety

Fire Pumps

Fire pumps are designed to supply water to the fire sprinkler system and its components at a higher pressure rate to effectively extinguish a potential fire. There are two main types of fire pumps: diesel and electric and they require different frequencies of maintenance and inspections due to their different components needs.

Fire Backflow

This equipment is designed to prevent water from flowing back into the main water supply. This prevents the water supply from being contaminated or polluted due to backflow.

How to Install (VFS, Of Course!)

At VFS Fire & Security Services we understand that your unique building needs unique fire protection systems. Our team is equipped to ensure you receive the fire protection you need to keep your building and your people safe from harm.