SANTA’S COMING DOWN THE CHIMNEY, AND SO IS A BURGLAR. ARE YOU KEEPING AN EYE ON YOUR OFFICE WHILE EVERYBODY’S OUT?

Most people know that crime escalates around the holiday season. Whether it be burglary, cyberattacks, or theft, it’s important that your business is prepared for everything. Understanding the importance of implementing proper security measures into your building is essential to the safety of your team.

WHAT SECURITY MEASURES SHOULD YOU BEGIN IMPLEMENTING TODAY TO PROTECT YOUR BUSINESS LATER?

START BY TRAINING YOUR EMPLOYEES ON PROPER PROTOCOL.

Inform your employees of the best ways to protect your business and those who work within it. Security efforts throughout your company will not work if your employees are not on board. This training should cover physical security protocols. It should also cover what to do if someone dangerous is within the facility as well as cybersecurity protocols.

Be sure your upper management has a large role in the implementation of security training and protocols. Upper management’s buy-in is essential. It helps ensure the rest of your staff understands the importance of the training. It also leads to greater follow-through with implementation.

ASIDE FROM EMPLOYEE EDUCATION, IMPLEMENT PROPER ACCESS CONTROL SYSTEMS.

Access control into your facility is one of the most straightforward ways to protect your business’ assets, inventory, and most importantly, your employees. An access control system that functions properly and is custom-tailored for your company is a powerful management tool. It helps to restrict access to certain rooms or track movement throughout your facility.

At VFS, our security experts understand what it takes to implement proper security controls. We design access control systems that also integrate into your intrusion alarm systems.

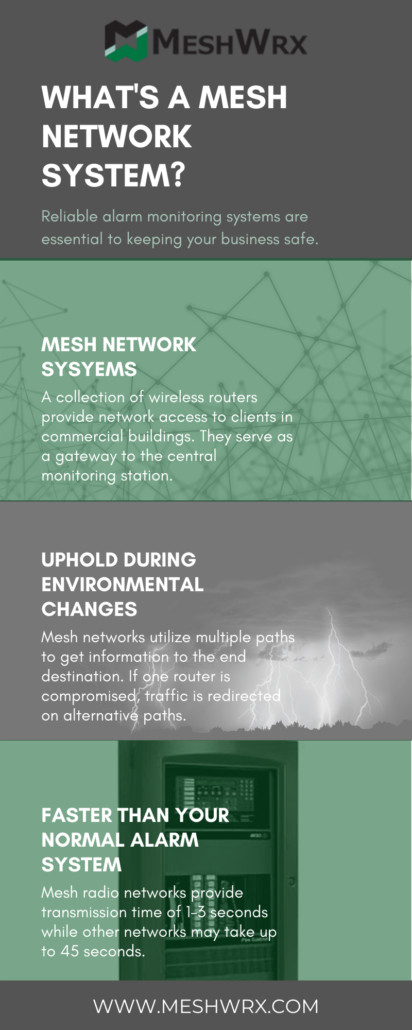

ANOTHER ASPECT TO CONSIDER IMPLEMENTING IS INTRUSION ALARM SYSTEMS.

Intrusion alarm systems not only deter trespassers, but they also alert you and the authorities when someone unlawfully enters your building. Because every client has unique needs for their security measures, we design your security plan to meet your specific needs. VFS’ alarm systems integrate into your access control and video surveillance to ensure you are covered in the event of an emergency.

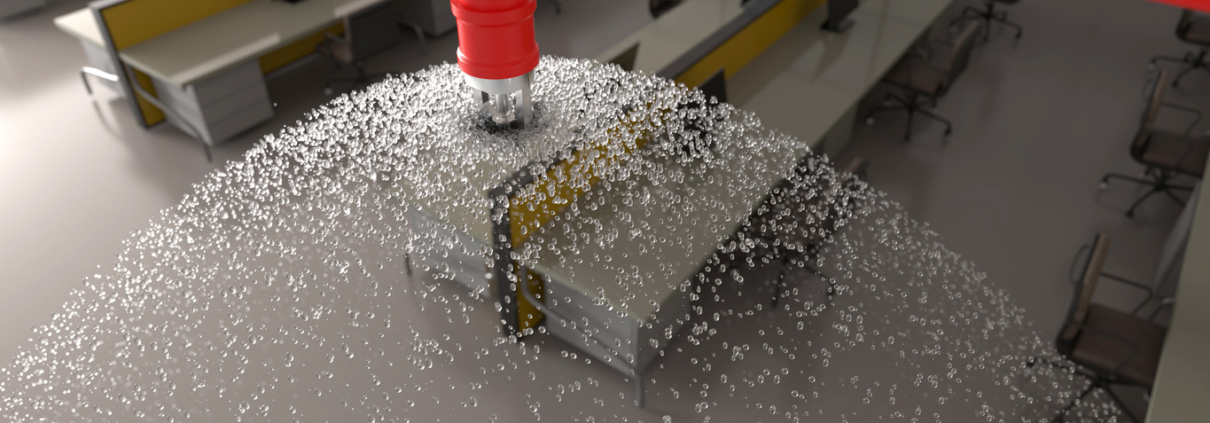

IMPLEMENT VIDEO SURVEILLANCE TECHNOLOGY TO PROTECT YOUR BUSINESS.

Video monitoring within your facility can help identify internal and external threats, like theft, vandalism, and workplace violence. Video surveillance deters people from actually performing these threats, while also making it easier to identify those that do.

We connect your video surveillance system to your IP network. This means historical footage and live video can be viewed from a computer anywhere you have internet access. These systems can also work in conjunction with your access control system to ensure your business remains safe and secure.

Implementing video surveillance technology into your business’ security plans can also lower insurance premiums. As the insurance companies see it, your risk goes down immensely with proper security systems in place.

LASTLY, REVIEW YOUR SECURITY SYSTEMS AND PROTOCOLS REGULARLY.

At VFS, we implement security measures for your specific business needs. In doing this we also analyze where your business might need more or less security. We track each client’s activity and reliability using an in-depth reporting system.

These analytics dictate our recommendations and information on which systems you use the most. It also helps to inform us where your business has the potential to improve.

Understanding where your business’ security needs work is essential to keeping your people and your business safe from harm. When you have the proper systems and processes in place, you’re ready to handle anything that may come your way. Contact us today to learn more about how we can help your business remain safe and secure.