WHILE THE KIDS ARE AWAY THE FIRE PROTECTION MUST STAY

School’s almost out for the summer!

Time to spend the next three months recovering from the last school year… Er, we mean preparing for the next school year! But before you all head off to the beaches for a long-anticipated vacation, ensure your building remains protected.

What do you know about fire protection for education buildings? As we say, though the kids may be away, the fire protection must stay.

Fire Protection… The Bare Minimum!

Educational facilities’ minimum fire protection and life safety requirements are outlined in NFPA 101: Life Safety Code. In this code, educational occupancies are defined as “any building used for educational purposes through the twelfth grade by six or more persons for four or more hours per day or more than 12 hours per week.”

This is expanded to include preschools and kindergartens that meet these requirements:

- The purpose of the building is primarily educational, even though the children who attend such schools are of preschool age

- The children are all 24 months of age or older

WHAT REQUIREMENTS ARE INCLUDED FOR EDUCATIONAL FACILITIES?

There are various requirements when it comes to fire protection for educational facilities. But what are they? Let’s discuss.

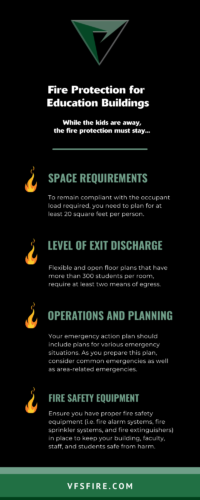

SPACE REQUIREMENTS

Determining your code requirements for your specific facility starts with the capacity of your building.

According to NFPA 101, the capacity of a building is assessed by calculating the occupant load of the space, which means how large the area needs to be based on the total number of people in the facility. To remain compliant with the occupant load required, you need to plan for at least 20 square feet per person.

The NFPA 101 code provides information on where and how students can be located in your building. For example, younger children must be located closer to the ground floor to make evacuation easier and more efficient. Classrooms for preschool, kindergarten, and first grade must be on the level of exit discharge.

Classrooms for second grade can be located no more than one floor above the level of exit discharge.

WHAT IS THE LEVEL OF EXIT DISCHARGE?

The level of exit discharge is defined as “the story that is either the lowest story from which not less than 50% of the required number of exits and not less than 50% of the required egress capacity from such a story discharge directly outside at the finished ground level; or where no story meets the conditions of the item (1), the story that is provided with one or more exits that discharge directly to the outside to the finished ground level via the smallest elevation change.”

Lastly, for education facilities, flexible and open floor plans that have more than 300 students per room, require at least two means of egress. They also must open to separate atmospheres. It’s important that your local fire marshal or authority having jurisdiction (AHJ) signs off on these floor plans and configurations.

Read on to learn more about AHJ.

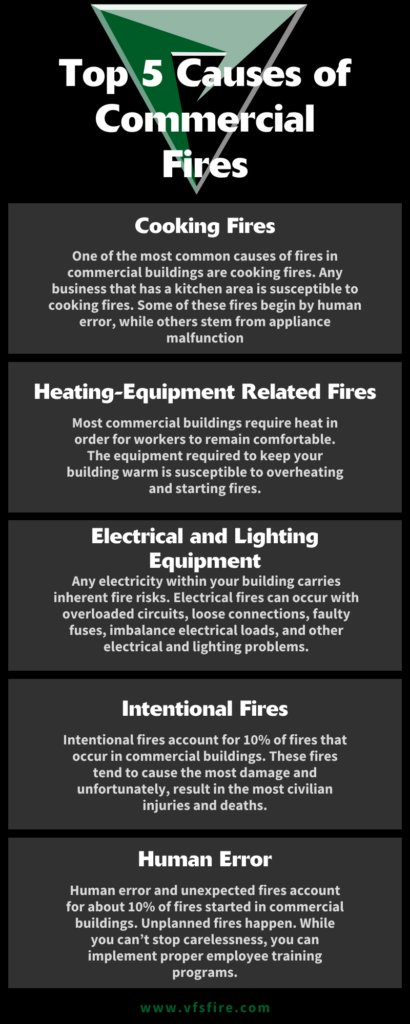

OPERATIONS AND PLANNING

Education facilities are required to have an emergency action plan to ensure building inhabitants remain safe from harm. The emergency action plan should include plans for various emergency situations.

As you prepare your emergency action plan, consider common emergencies as well as area-related emergencies. On a basic level, without area-specific emergencies in mind, you should include the following in your action plan:

- A procedure for reporting emergencies

- Evacuation, relocation, and shelter-in-place procedures

- Elevator use details

- Occupant and staff response information

- The design and conduct of fire drills

- The various fire protection systems and their coverage areas

- Other information required by local jurisdiction and fire authorities

It’s important you define which administrators will be responsible for the emergency action plan creation process as well as which positions will be responsible for managing it in the event of an emergency.

Educational facilities should conduct and document fire and emergency egress drills at least once per month when school is in session. In these drills, all building occupants must participate and all alarms must be activated.

Staff members should inspect all exit areas and ensure stairwells, doors, and exit passageways are clear, unobstructed, and in proper working condition. Moreover, these inspections should be documented.

A final note: For schools, there are very specific requirements regarding what items can be placed on the walls. Fire codes only allow for 20% of a wall area to be covered with art and paper products as they are extremely flammable. If fire sprinklers are installed throughout the school, that coverage can be increased to 50% of the wall area.

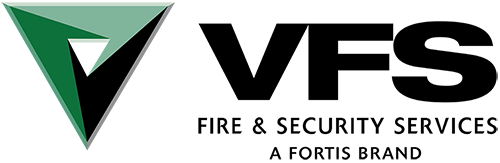

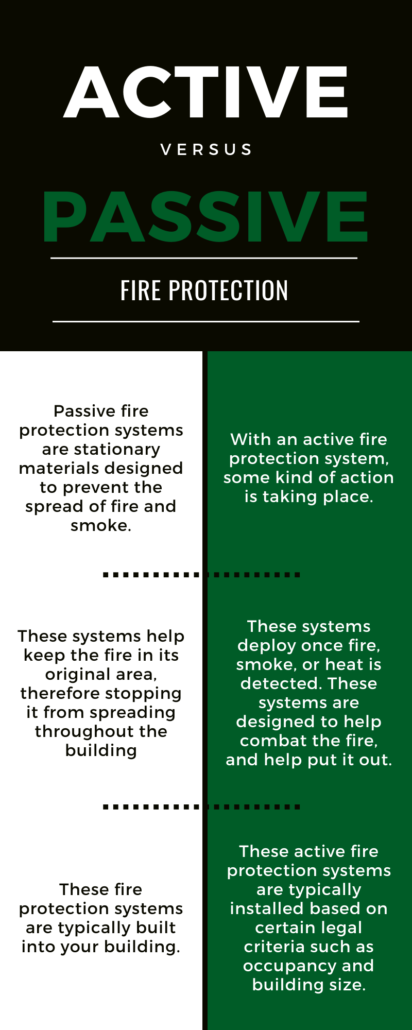

FIRE SAFETY EQUIPMENT

Ensure you have proper fire safety equipment in place to keep your building, faculty, staff, and students safe from harm. Let’s dive into what equipment is essential.

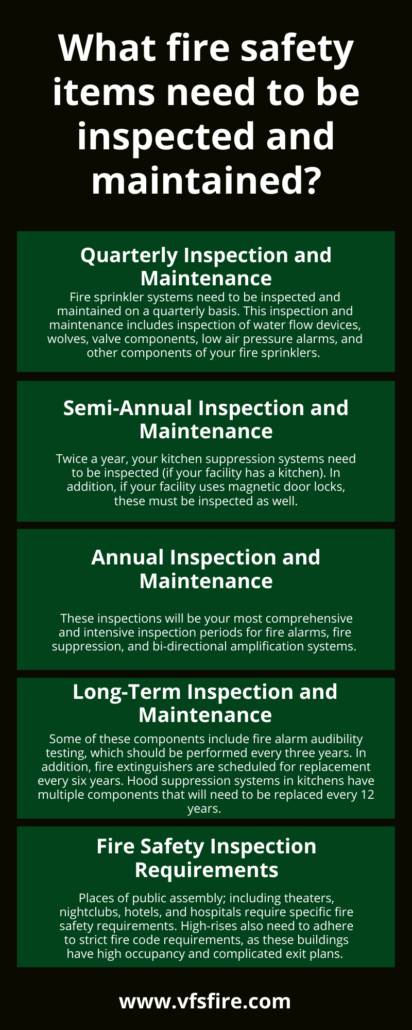

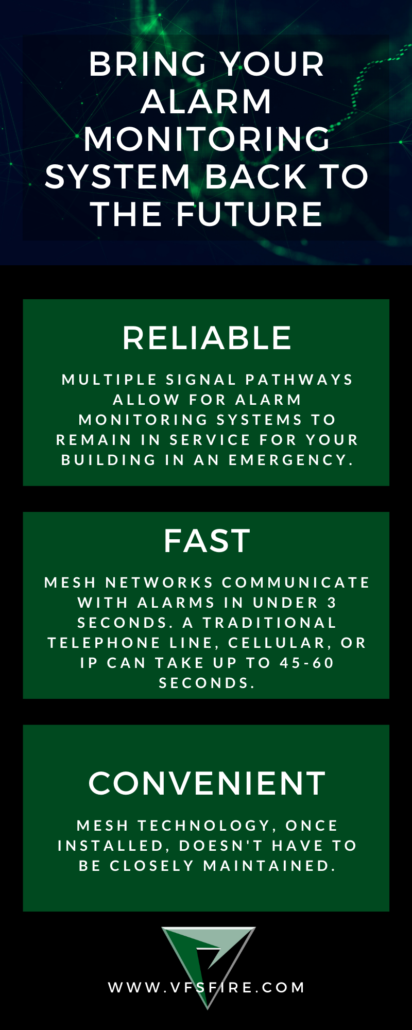

FIRE ALARM SYSTEMS

Educational facilities typically require fire alarm systems. Small facilities that are no larger than 1,000 square feet, with a single classroom, and located further than 30 feet from another building, however, can be without fire alarms. For example, this includes mobile or portable buildings that are utilized as classrooms and spaced 30 feet from the school and other mobile classrooms.

There are multiple exceptions and specifications depending on specific facility needs that may affect fire alarm implementation. This may include:

- The elimination of manual alarm pull stations

- Or, the addition of a mass notification or emergency alarm communication system

In order to understand your specific building needs, contact a fire safety expert, like our team at VFS!

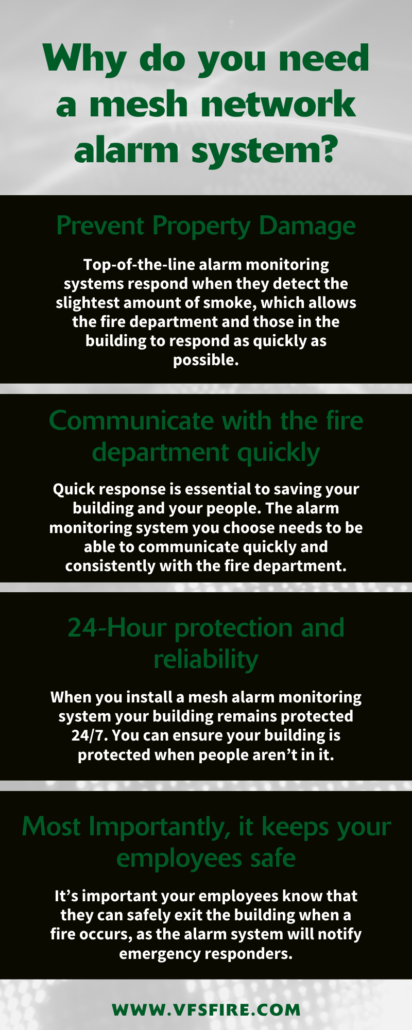

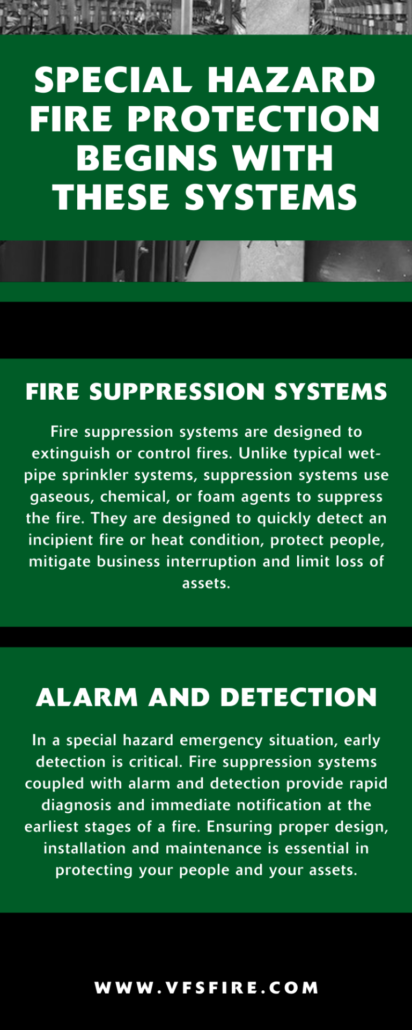

FIRE SPRINKLER SYSTEMS

A building greater than 1.000 square feet with multiple rooms requires an automatic fire sprinkler system. Additionally, all kitchens and cooking appliances should be protected with special hood and fire suppression systems.

Read on for further fire sprinkler system updates.

FIRE EXTINGUISHERS

Lastly, education facilities require fire extinguishers to be installed throughout the building. The specific placement and number of extinguishers are determined by the size and the layout of a building. Extinguishers should be installed, tested, maintained, and selected following NFPA 10, the standard for portable fire extinguishers.

Our team at VFS Fire & Security Services is equipped to help support your unique fire safety needs. We firmly believe in building long-lasting relationships with our clients. From planning to implementation to testing and maintenance, our services are always tailored to meet our clients’ specific needs.

Read on for tips on how to use summer vacation as a tool to get your fire safety up to par, then get in touch with our team today.