An article written by Randy Nelson, CEO of VFS Fire & Security Services, for the June 2012 issue of Sprinkler Age.

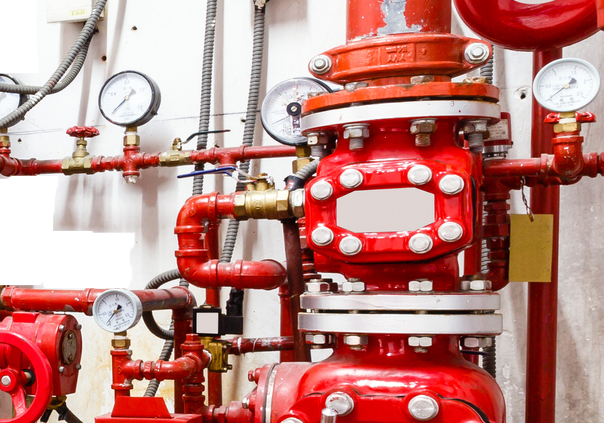

Although ‘shared support structures’ are nothing new to our industry, the term and additional guidance concerning hanging and seismic bracing when utilizing shared support structures required some long-deserved attention. Shared support structures can be loosely defined as structures that support more than one object (pipe or equipment) including components from other mechanical disciplines. Examples of shared support structures are trapeze hangers, pipe stands, pipe rack structures, and other similar assemblies. It is not intended that permanent structural elements of a building or the building itself be included as a shared support structure.

Read more